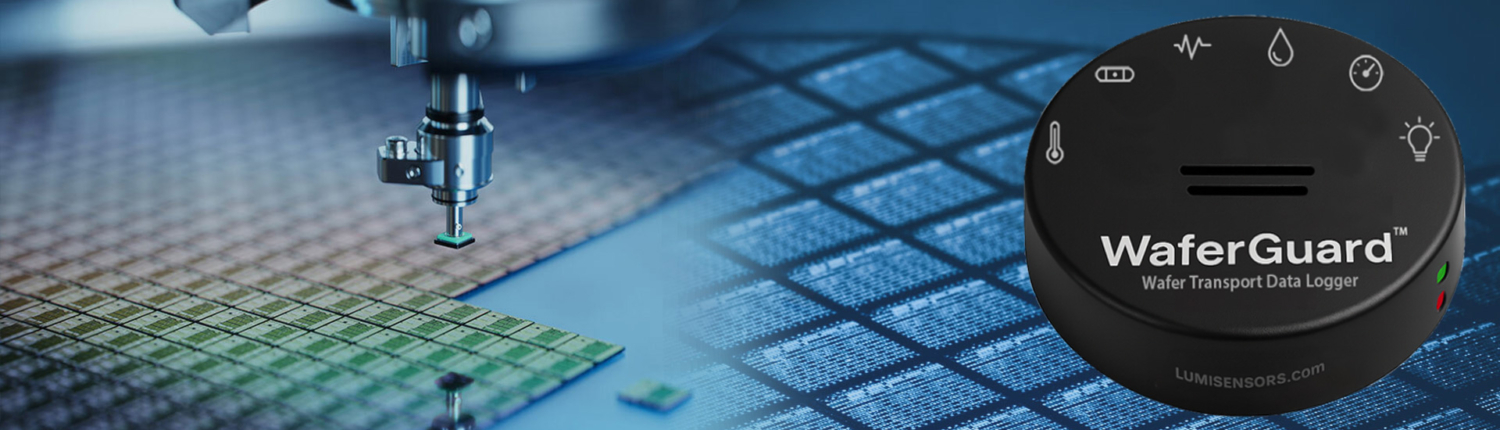

WaferGuard™ is the industry’s most advanced non–real-time wafer transport monitoring solution. Designed to fit seamlessly inside a standard 300mm or 200mm wafer cassette or FOUP, WaferGuard™ records critical environmental and handling conditions throughout the shipping process. At the destination, simply connect the device to download a complete journey report, helping you safeguard yield, ensure compliance, and optimize shipping processes.

By providing a complete digital report at the shipment’s final destination, WaferGuard™ helps chip manufacturers, logistics providers, and quality managers analyze transport conditions, optimize shipping routes and practices, and reduce costs from damage or delays.

Key Benefits

- Improve Yield & Reduce Loss – Identify transit events that can cause wafer damage before they impact production.

- Comprehensive Monitoring – Records temperature, humidity, vibration, tilt, light, and pressure.

- Seamless Fit – Designed with wafer-like dimensions to fit securely inside standard FOUPs and wafer cassettes.

- Data-Driven Decisions and Traceability – Post-trip analytics provide insight into handling practices and route conditions.

- Reusable & Cost-Efficient – Rugged, wafer-shaped design supports shipment along real semiconductor wafers.

- Efficiency – Battery powered with automatic reset for continuous reuse for future shipments.

Technical Specifications

| Wafer Sizes | 100mm, 150mm, 200mm or 300mm compatible (4″, 6″, 8″ and 12″ wafers) |

|---|---|

| Onboard MEMS Sensors | Temperature, Humidity, Vibration, Tilt/Level, Light and Pressure |

| Vibration Range | 6-Axis MEMS accelerometer; low and high acceleration (up to ±320g), gyroscope and tilt Vibration sensor is trig-gered if shock/vibration is sensed at ±16g or higher |

| Temperature Range and Accuracy | -20°C to 60°C, ±0.5°C |

| Humidity Range | 0% to 100% RH, ±2% accuracy |

| Data Capture Rate | Every 10 minutes |

| Battery Life | Rechargeable Lithium Polymer Battery 3-6 months of continuous operation with full charge |

| Carrier Wafer/Substrate | Carbon Fiber, Matt finish |

| Overall Thickness and Weight | Less than 500 grams, 16mm thick |

| Connectivity for data download | USB-C port |

| Onboard Memory | For recording data during each transport |

How it Works

- Load WaferGuard™ into a standard wafer cassette or FOUP alongside your wafers.

- Ship as normal—WaferGuard™ records conditions continuously throughout transit.

- Download the full trip report and raw log file at the destination in CSV format.

- Analyze & Optimize – Identify risks, improve packaging, and optimize for best logistics routes.

Applications

- Front-End Wafers – Protect sensitive, high-value wafers during long-distance shipment.

- Back-End Process Wafers – Verify safe transport of processed wafers before packaging.

- Tool Relocation & Installations – Ensure wafer handling safety during equipment moves.